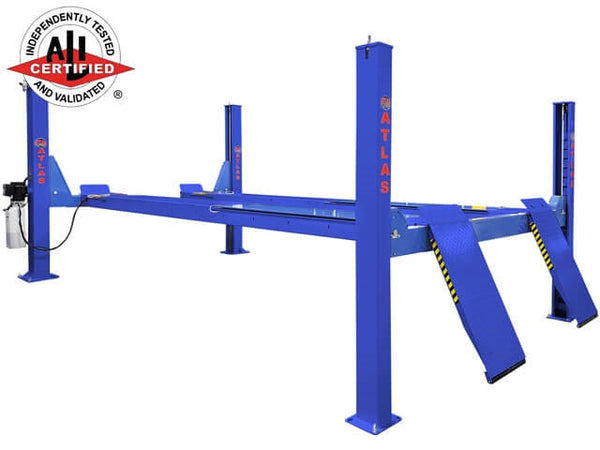

The Atlas® 12AWFSL 12,000 lb. alignment scissor lift has been in production for several years and hundreds of these lifts have been sold throughout the world except for the North America.

Atlas® Asian partner developed this lift in a joint venture with one of the most prestigious Italian lift manufacturers. The combination of the Italian engineering and design coupled with the low cost of the Asian labor has resulted in an alignment lift that is equal to or better than similar big name lift brands costing two and three times as much money.

The Atlas® alignment lift has a lifting height of over seven feet so that it may be floor mounted or recessed if the customer decides on a flush mount installation. The full frame under the scissor lift provides for maximum stability.

All Atlas® alignment scissor lifts can be surface mounted or flush mounted. Each lift comes with approach ramps for the floor mounted application or an optional set of ramps if the customer decides to flush mount the lift. Check the technical specifications to better understand how the extra high lifting height allows the Atlas® 12K alignment scissor to be flush mounted and still offer plenty of room under the runways to properly access the underside of the vehicle.

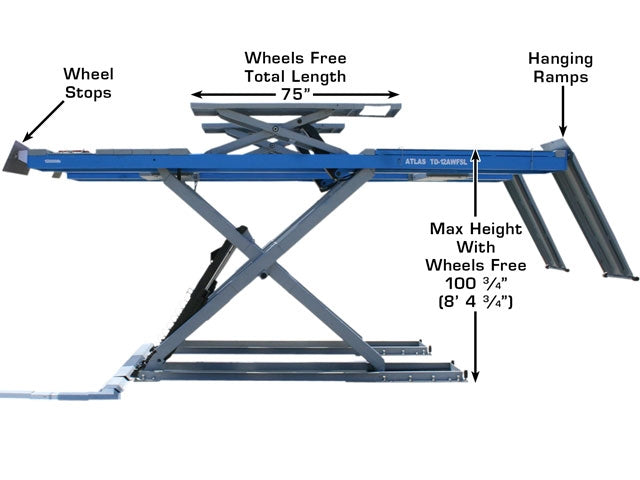

Wheels Free System

This lift features a wheels free runway jack system. The wheels free runway jack system has the same style air actuated lock system as the Atlas 12ASL. When fully extended, the wheels free system elevates to over 17 inches above the runway. This method is a perfect quick lift for a perimeter framed or unibody vehicle. The wheels free jack system is not designed to lift straight framed vehicles, because most straight framed vehicles have narrower lifting points than a unibody vehicle.

The wheels free system can be controlled from either the control panel or from a wired remote. This wired remote allows the customer to actuate the wheels free system from many different positions around the scissor lift.

The telescoping wheels free lift platform can be extended for longer wheels based vehicles. Standard heavy duty rubber supports are used to prevent damage to the lifting surfaces of the vehicle.

The extra long 53" long approach ramps make it easy to load low riding vehicles.

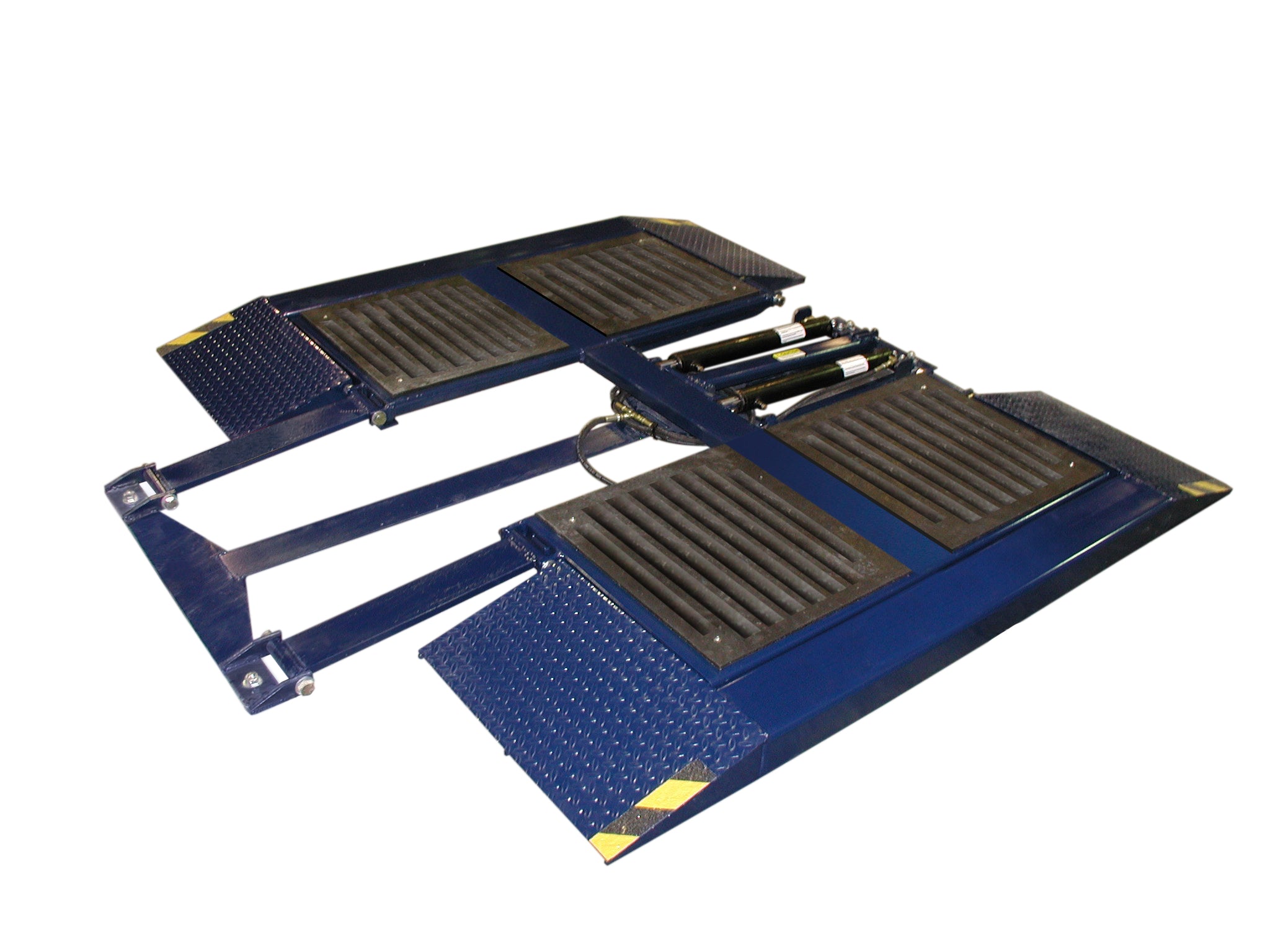

Optional RJ-6 Rolling Jack

Once a vehicle is positioned on the Atlas® alignment scissor lift, the optional Atlas® RJ-6 rolling jack can lift the vehicle off of the runways to perform wheel service. The air powered hydraulic Atlas® RJ-6 rolling jack has telescoping arms that extend over the runways to access lift points. These jacks have screw out extensions or optional stack on truck adapters.

Welded rails on the inside of the runways are standard on all lifts, allowing the customer the option of incorporating the Atlas® RJ-6 rolling jack system on his Atlas® alignment scissor lift.

Quality workmanship, ease of operation, straight forward installation instructions, a durable powder coat finish and the lowest prices in the Industry makes the Atlas® 12AWFSL 12,000 alignment scissor lift the perfect choice for the demanding and discriminating shop owner.

Worried about bay space? An Atlas Alignment System allows the customer to utilize a minimum amount of space and still be able to align the smallest foreign car all the way up to a one ton dual rear wheel pickup truck.